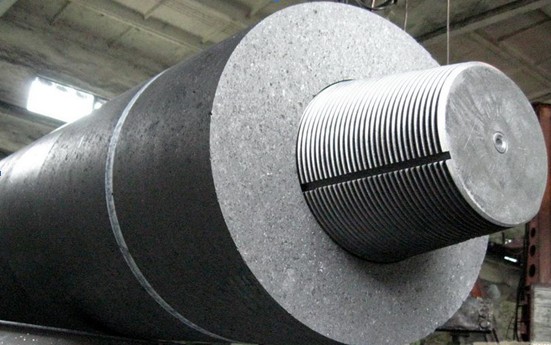

Graphite electrodes are mainly used in EAF and LF for steel making. Supply various NP, HP, UHP grade Graphite Electrodes(Ø75mm — Ø700mm) with nipples.

Our electrodes have the properties of superior electric conductivity and chemical stability, low ash, thermal conductivity, high mechanical strength, antioxidation and corrosion resistance in high temperature.

Standard sizes of electrode

|

Specifications(inch) |

Allowable Diameter(mm) |

Allowable Length(mm) |

||||

|

Nominal Diameter |

Max. |

Min. |

Nominal Length |

Max. |

Min. |

|

|

12 |

300 |

307 |

302 |

1800 |

1875 |

1700 |

|

14 |

350 |

357 |

352 |

1600 |

1700 |

1500 |

|

1800 |

1875 |

1700 |

||||

|

16 |

400 |

409 |

403 |

1600 |

1500 |

1500 |

|

1800 |

1875 |

1700 |

||||

|

2100 |

2175 |

1975 |

||||

|

18 |

450 |

460 |

454 |

1800 |

1875 |

1700 |

|

2100 |

2175 |

1975 |

||||

|

2400 |

2475 |

2275 |

||||

|

20 |

500 |

511 |

505 |

1800 |

1875 |

1700 |

|

2100 |

2175 |

1975 |

||||

|

2400 |

2475 |

2275 |

||||

|

22 |

550 |

562 |

556 |

2100 |

2175 |

1975 |

|

2400 |

2475 |

2275 |

||||

|

24 |

600 |

613 |

607 |

2100 |

2175 |

1975 |

|

2400 |

2475 |

2275 |

||||

|

2800 |

2850 |

2550 |

||||

|

26 |

650 |

663 |

657 |

2400 |

2475 |

2275 |

|

28 |

700 |

714 |

708 |

2400 |

2475 |

2275 |

|

2800 |

2850 |

2550 |

||||

Nipples: 3TPI or 4TPI

1. Micro-pore carbon block

Micro-pore carbon block is manufactured with high-temperature electric calcined anthracite as the main raw material, baked at high temperature, and accurately machined.It has better properties of porosity and permeability, good resistance to erosion of liquid, and suitable for the bottom and hearth of a blast furnace.

2. Super micro-pore carbon block

Super micro-pore carbon blocks have better properties of high thermal conductivity, the micro index and better permeability index, can reduce the furnace body erosion rate, effectively prevent the molten iron permeation erosion

3. Semi-graphite carbon block

Semi-graphite carbon blocks mainly have the certain thermal conductivity, excellent anti-alkaline. It is economic and practical, and can meet the basic needs of the blast furnace. It is mainly suitable for the bottom of blast furnace

4. Graphite block

Graphite block is manufactured, with low ash petroleum coke as the main raw material, through forming, baking, impregnation, re-baking, graphitization, and accurate machining.

It has very high thermal conductivity. It is more effective to cool the bottom, reduce the bottom temperature, slow down the hearth erosion. It is suitable for hearth and bosh of blast furnace.