Ladle turrets is one for the very important part of continuous casting plant, it holds the pouring ladles, which weigh up to500 t. The world’s largest ladle turret till now reaching 520t on single arm, manufactured in China. By means of the ladle turret, the pouring ladles are alternately slewed into pouring and charging position. This function ensures the uninterrupted operation of the continuous casting plant. While one ladle is emptied, a full ladle is provided on the other side. They ensure safe and reliable manipulation of heavy lades that contain the liquid steel bound for the continuous caster.

From the ladle, the hot metal is transferred via a refractory shroud (pipe) to a holding bath called tundish. The tundish allows a reservoir of metal to feed the casting machine while ladles are switched, thus acting as a buffer of hot metal, as well as smoothing out flow, regulating metal feed to the molds and cleaning the metal.

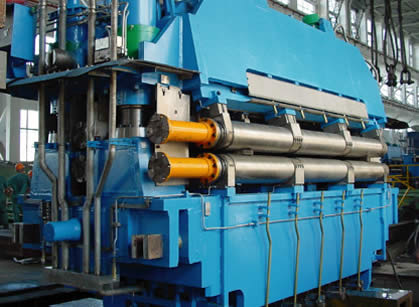

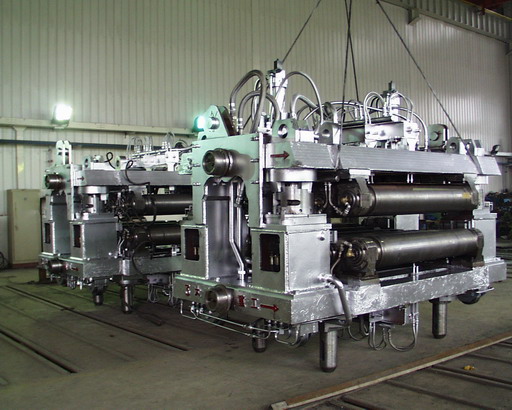

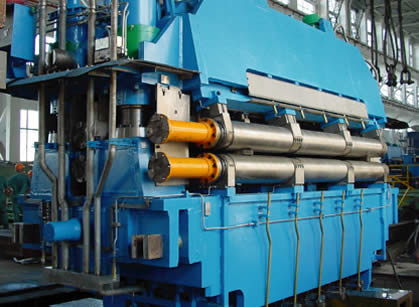

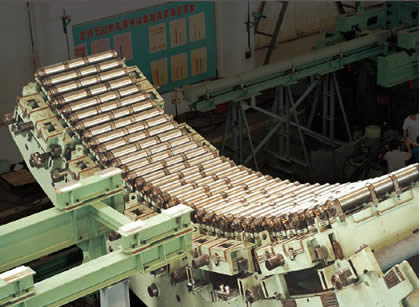

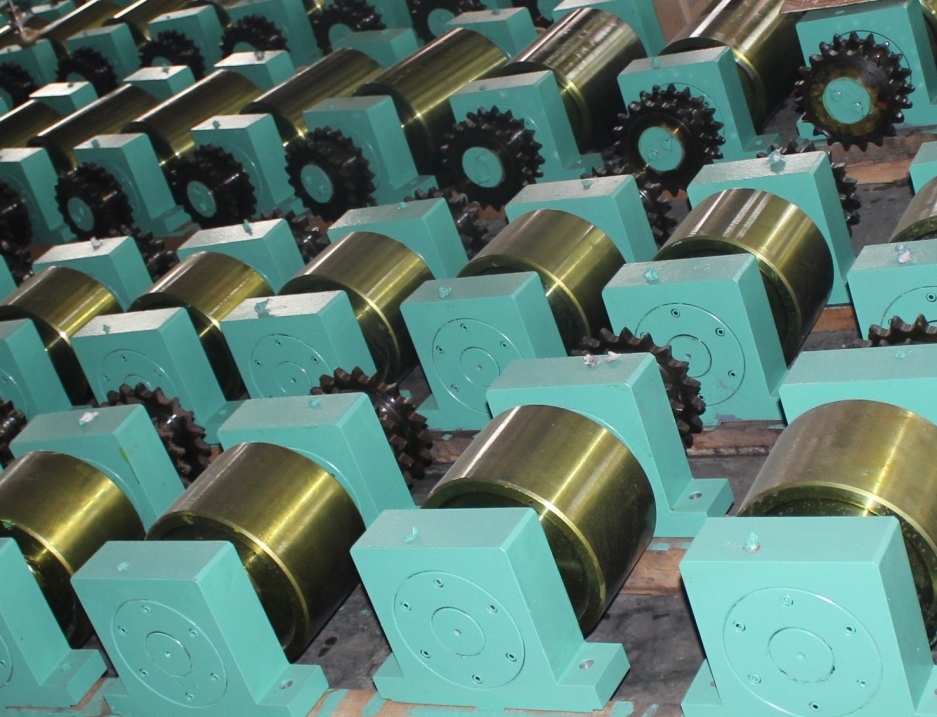

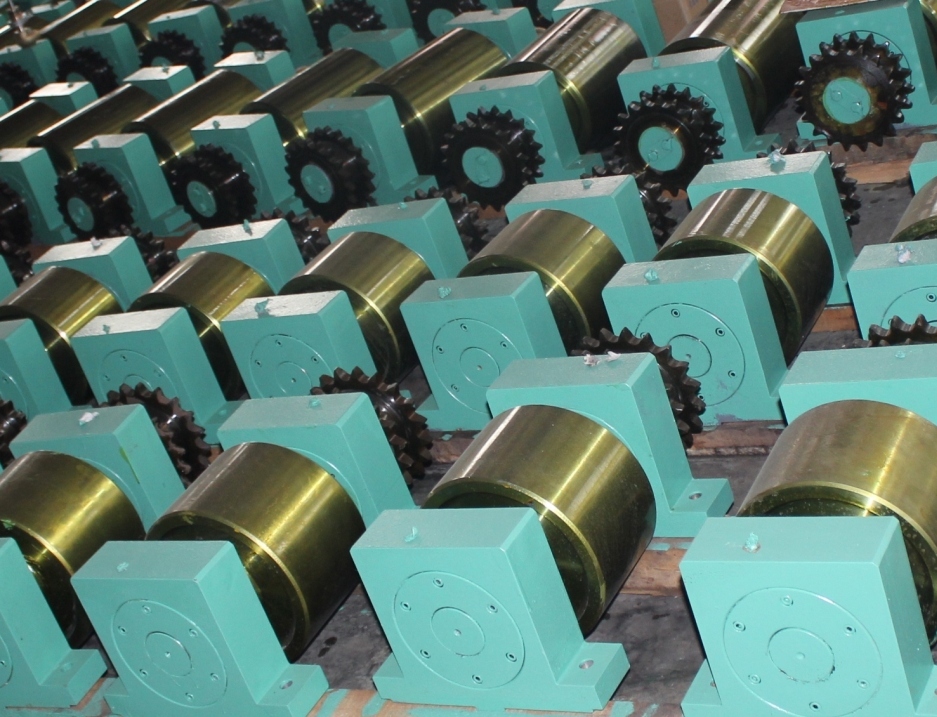

Segments are indispensable in the process of continuous casting. CLIK are one of the best suppliers of segments and relevant spare parts for billet/round/bloom/slab continuous casting machines.

The units included the vertical bending segment, bow segment, straightening segment, horizontal segment, bow support frame, horizontal support frame, segment up and down frame, roller holder beam etc.

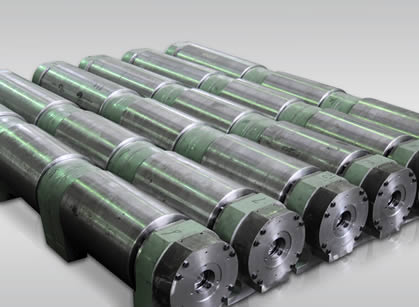

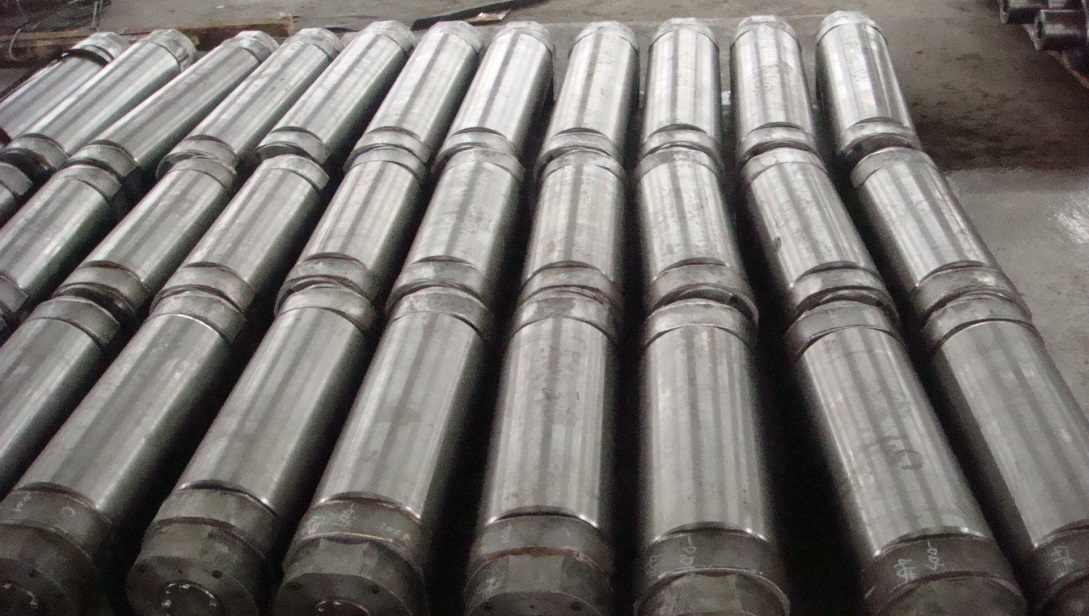

CCM efficiency depends significantly on the reliability and durability of the guiding mechanism in the secondary cooling zone. The basic operating elements of the guiding mechanism are rollers of various diameters.

We are reliable partner for your specific requirements for spare rollers, bimetallic rollers with deposited layer, roller jackets and all other roller components.

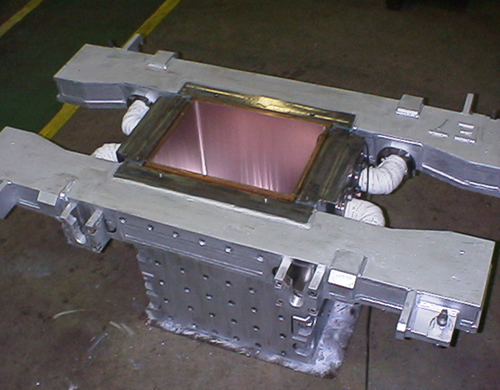

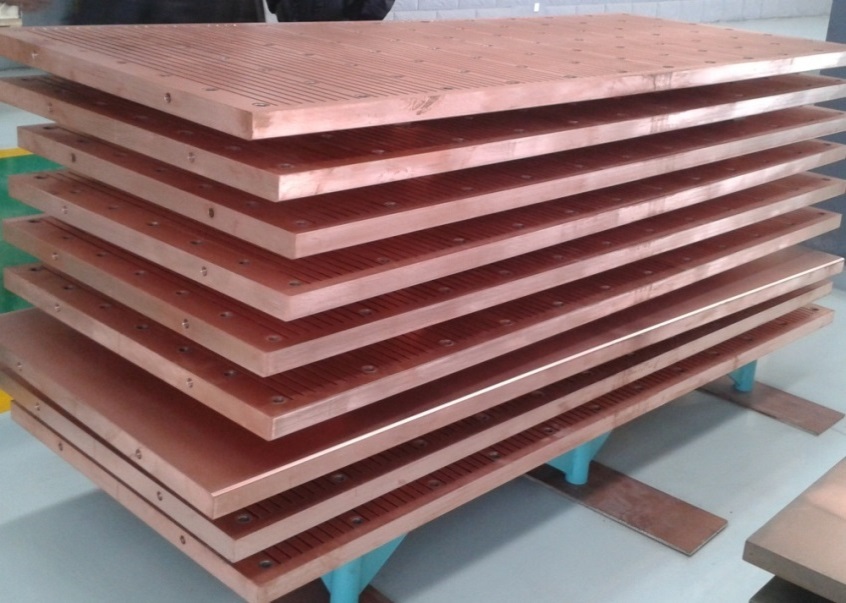

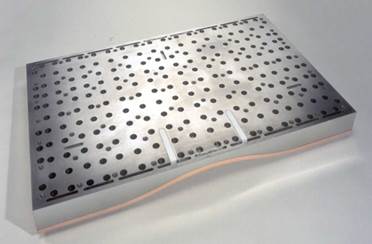

Moulds is to solidify the liquid steel poring through the submerged entry nozzle, guarantee required billet/bloom with enough thicken shell to be obtained. Moulds are very important for continuous casting efficiency increasing and the cast quality improvement. We supply variety round, square, rectangular and beam blank mould assemblies with excellent performance.

Production specifications: (covered all size)

Taper designing: Providing the different productions, including single taper, double tapers, parabolic taper and polygon taper.

Materials: DHP, CuAg, CuCrZr etc.

Coating: Cr, NiCo+Cr

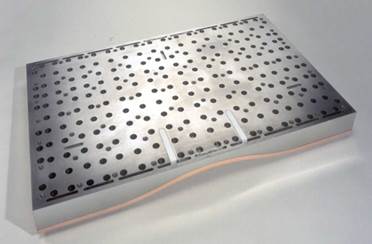

Conventional mould plates, thin slabs, beam blank copper mould assembly, CSP and build-up moulds

Dim: from 120×850mm to 3600×1000mm

Thickness: 40mm-55mm

Material: CuAg, CuCrZr

Coating: NiCo, NiCo+Cr, Ceramic coating

Dummy bar also called the starter bar, is used to tract and lead the cooled and solidified strand and pull it out by the withdrawal and straightening machine.

Supply rigidity Dummy Bar and flexible Dummy Bar as customers’ requirement with the features of long service life and stable performance.

The roller table is intended for the transportation of billet from the secondary cooling table to the straightener. Roller tables with excellent performance and low maintenance cost.

Straightener is used to lead the dummy bar and withdrawal and straightening the strand.Our straighteners can operate continuously under the severest of conditions, requiring only minimal planned maintenance, with lower energy consumption and long service life.