Various of circular saw blades with more than 2,000 specifications, including metal hot-cutting circular saw blade (Φ800-2500mm), metal cold-cutting circular saw blade (Φ300-1600mm), TCT circular saw blade (Φ300-2200mm), HSS segmental circular saw blade (Φ630-1430mm), and diamond circular saw blank (Φ300-3500mm).

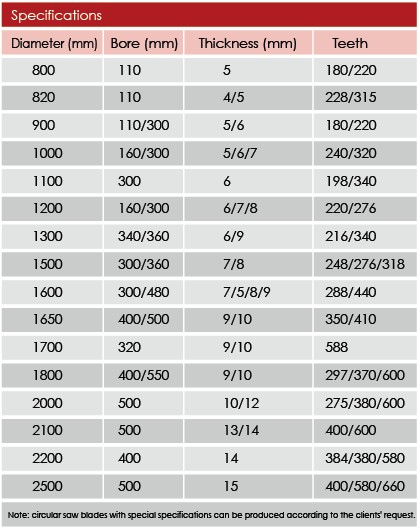

Metal hot-cutting circular saw blade

Metal hot-cutting circular saw blade can be applied for cutting steel bar, steel tube and steel sections made of carbon steel, alloy steel, bearing steel, and HS tool steel. The cutting temperature is over 750°C. It is made of good spring steel with the process of heat treating and machining. Excellent mechanical property of the body as well as the high hardness and abrasion performance of the teeth tip ensure the instant cutting with safety and quality.

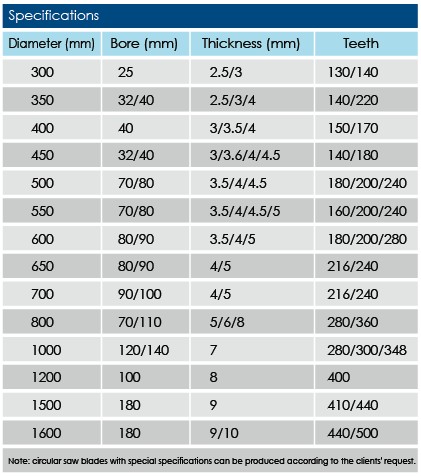

Metal cold-cutting circular saw blade

Metal cold-cutting circular saw blade can be utilized for cutting ERW tubes and cold-rolled steel section like H-beam, I-beam, channel steel, angle steel, etc. under the normal temperature. It is made of good spring steel and low alloy steel with the process of heat treating and machining. It features in good rigidity, high intensity as well as convenient operation.

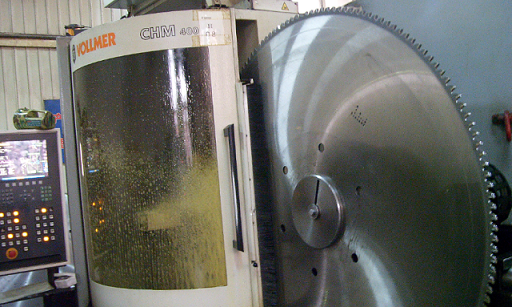

TCT circular saw blade

TCT circular saw blade for steel is one metal cutting tool equipped with special sawing machine. It is combined with tungsten carbide tips brazed onto the alloy steel body. Its cutting efficiency can be 5-10 times of traditional HSS segmental circular saw blade. The diameter range we can produce now is 320-2200mm. It is suitable for cutting rounds, pipes and sections made of carbon steel, alloy steel, casting steel, aluminum, copper, etc. in the industries like sections mills, pipes mills, rail mills and machinery mills.

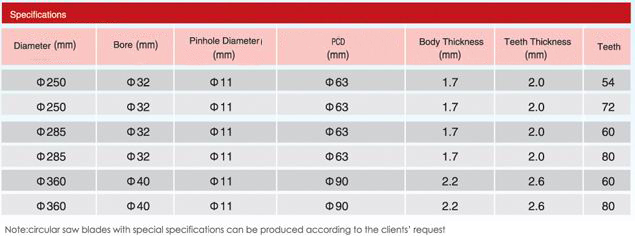

Ultra-thin TCT Circular Saw Blade is made of special material through special process and suitable for cutting all kinds of metal rounds, pipes, etc. It features in good mechanical properties, high wear-resisting properties, excellent cutting quality, high cutting efficiency, power saving, material saving, noise reducing, safety operation, etc.

Its cutting width is only about 1.5 times of band saw, but the cutting efficiency is 10 times of that and has better cutting quality. So it is widely applied as material cutting or sampling in precise machinery, auto industry and metallurgical industry. It will be definitely the substitutes for band saw, traditional circular saw blade and shear cutters.

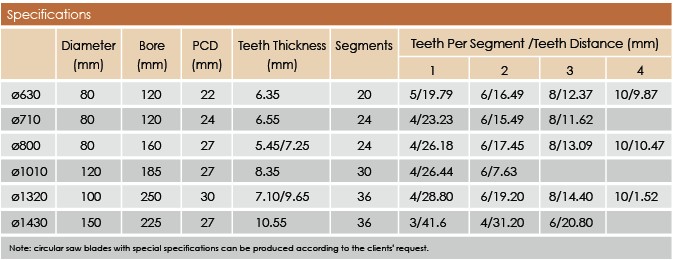

HSS segmental circular saw blade is combined with HSS segments mounted onto alloy steel body through rivets. It can be used for cutting all kinds of billets and sections made of carbon steel, alloy steel and casting steel.

Band Saw Blades

Various bi-metal band saw blades for metal cutting, products are involved in M42, Powder HSS, Carbide band saw blades with excellent quality and professional performance.